Loftis Manufacturing, Inc. was incorporated in 2003 and through the years the company has continued to grow and evolve.

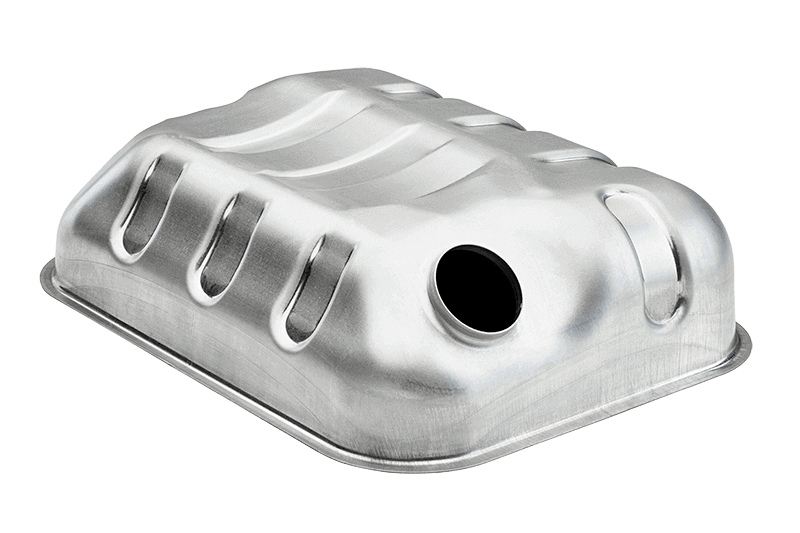

Starting as a design only company, Loftis Manufacturing, Inc. has since evolved to include tool and die assembly and tryout as well as manufacturing of details and mid-size metal stampings.

We are proud to serve the automotive, aerospace, medical & commercial industries.

Contact us to get a quote for your product needs.